Interlock gloves are an essential component of personal protective equipment (PPE) in many industries. Designed with a double layer of knitted fabric, these durable and flexible gloves provide hand protection while remaining breathable and allowing dexterity for detailed tasks.

In this comprehensive guide, we’ll explore the key features of interlock gloves and examine how to choose the right pair for your needs. We’ll also cover proper care and common applications across sectors like manufacturing, food service, and healthcare. With the right knowledge, you can select high-quality interlock gloves tailored for safety and performance.

What Are Interlock Gloves?

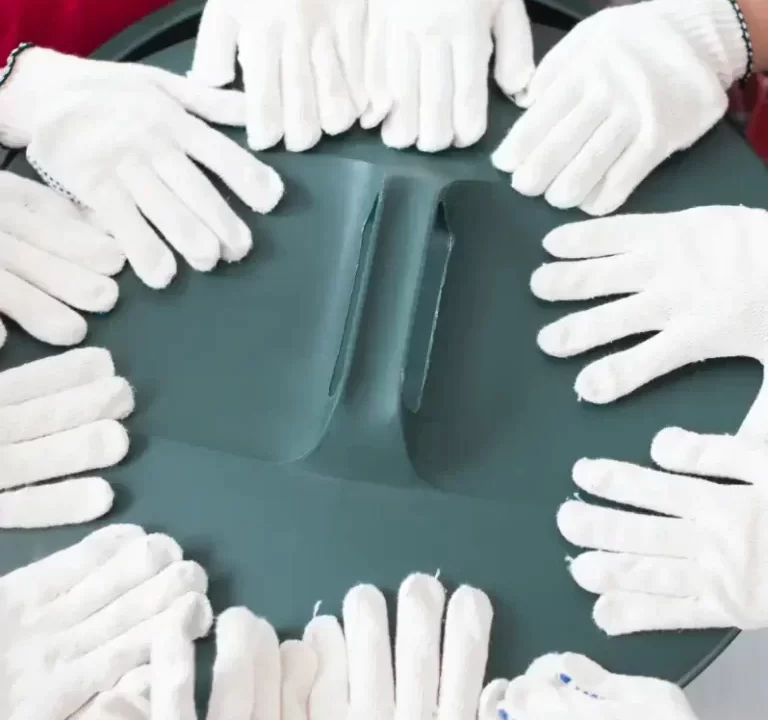

Interlock gloves feature a double layer interlock knit construction that provides durability and protection. The inner fabric layer has fine gauge knitting, while the outer layer features heavier knit for abrasion resistance.

This innovative design allows interlock gloves to be:

- Flexible and dexterous: The stretchy knit material moves easily to facilitate detail-oriented tasks. The snug fit also improves grip control.

- Breathable: Air can circulate between the two layers, keeping hands cool. This makes extended wear comfortable across work shifts.

- Protective: The outer knit layer serves as armour against abrasions, punctures, chips, and shards. This protects hands without limiting mobility.

Common materials used to construct the dual layers include nylon, polyester, and Kevlar. These can be blended for the ideal balance of breathability, dexterity, and protection.

Key Features and Attributes of Interlock Gloves

Protection Levels

Interlock gloves come in varying grades of protection. Lower grades, like ANSI Level 1, provide abrasion resistance for basic tasks. More rugged ANSI Level 3+ options can include reinforced palms and fingers, ideal for heavy-duty industries involving glass or metalwork.

Hi-viz color variants improve workplace safety and visibility for active, fast-moving worksites. Some high cut models even protect forearms and wrists when handling debris or sharp items.

Dexterity and Sensitivity

Unlike rigid leather gloves, the flexible knit construction of interlock gloves allows excellent dexterity. The snug fit also improves overall grip and control for detailed work like product assembly or inspection, equipment operation, and handling small parts.

With conductive models, the interlock fabric can incorporate touchscreen fingertip pads for use with smart device interfaces.

Comfort and Breathability

Thanks to their knit fabric and form-fitting design, interlock gloves deliver outstanding comfort through long shifts. The dual layers don’t restrict movement while working. Air circulates between the inner and outer glove lining as well, keeping hands cool and dry over hours of active use.

This results in fewer hand fatigue issues linked to sweat buildup and overheating in thicker glove types. Breathability also means users can comfortably wear interlock gloves for extended periods each workday.

Easy Care and Maintenance

Most interlock glove models are fully machine washable, retaining their protective qualities through repeated industrial laundering. This convenient care method saves on replacement costs compared to easily soiled leather gloves.

Some public use variants also incorporate antimicrobial technology into the knit lining to protect against odour and bacterial buildup with heavy use. This also extends product lifespan with consistent wash and wear performance.

Choosing durable interlock gloves that balance key protective qualities with comfort, dexterity and easy care helps maximize value over thousands of hours of repetitive use.

Factors to Consider When Selecting Interlock Gloves

Task Safety Requirements

The first factor to examine is the type of hazard protection needed for the intended work activities before purchasing any safety work gloves. Will hands be exposed to abrasions, cuts, punctures, heat, vibration or chemical risks? Prioritizing safety for the specific job ensures you choose adequate protection.

For example, food processing roles involve slick instruments and cutting equipment warranting high cut-resistance ratings. Medical applications might prioritize chemical resistance for handling harsh disinfectants. Make safety the number one criteria based on local workplace risk assessments.

Environmental Conditions

Also examine if heat, cold, or wetness are concerns in the local working conditions. Breathable, moisture-wicking gloves promote hand health in hot settings like foundries or boiler rooms. Water-resistant coatings repel liquids to keep hands dry across long shifts.

Cold storage and food refrigeration areas need insulated glove options to prevent dangerous chill and improve grip. Analyze all environmental factors that hands will contact through daily tasks.

Durability and Care

The knit construction of interlock gloves balances durability with comfort and flexibility. Still, examine expected lifetime based on hours of use and laundering capability. Can they withstand daily use plus hot water washing or steam disinfection?

Long term costs also depend on whether gloves are shared publicly or individually assigned. Proper care and maintenance are essential for longevity as well.

Fit and Sizing

An accurate fit determines control, flexibility and how well interlock gloves protect against hazards. Measure hand dimensions like palm width and length to identify ideal size options.

Trying gloves on before purchase ensures optimum fit. The snug stretch fabric should align smoothly without looseness or tight spots that hinder movement. Most brands now offer narrow, standard and wide size profiles to suit varied hand shapes.

User Comfort and Breathability

Evaluate working conditions and shift length. Breathable, moisture-wicking gloves with ventilated cuffs promote airflow to keep hands drier and cooler all shift long. This boosts comfort while preventing fatigue, stress injuries and problems gripping tools.

Analyze fabric blends to balance durability with breathability, flexibility and comfort based on the environment and timeline personnel will wear gloves actively.

Key Applications of Interlock Gloves Across Industries

Manufacturing and Warehousing

The manufacturing sector widely uses interlock gloves to prevent cuts, abrasions and burns while handling raw materials and operating machinery. Tough ANSI Level 3 options withstand the rigors of Assembly line tasks involving contact with sharp stamped metal pieces or molded plastic edges even after hundreds of production cycles.

In warehouses, the knit fabric and snug fit facilitate working with small parts and packaging materials without loss of dexterity. High visibility colors also boost safety for moving stock around busy fulfillment centers with heavy forklift traffic.

Automotive and Aviation

Whether conducting test drives or inspecting aircraft, interlock gloves enable technicians to handle assorted fluids, fuels, oils and solvents safely. Those rated for chemical resistance provide an impervious barrier when manipulating caustic or irritating substances needed for maintenance procedures.

The sensitivity of the stretch fabric still allows grasping tiny fasteners or manipulating delicate electronics without removing hand protection. This fine motor control heightens precision essential during complex repairs.

Food Production and Agriculture

In commercial kitchens, food processing plants and farms, cut-resistant interlock gloves provide a nimble barrier against sharp slicing instruments. Unlike easily soiled cloth or leather options, the rugged knit construction withstands heavy-duty use and endless laundering.

Breathable, flexible interlock gloves promote proper food handling hygiene as excess hand moisture can transfer and cause cross contamination. This makes interlock gloves ideal for both food safety and employee hand protection when facing hours of repetitive slicing, whisking, or packing tasks.

Janitorial Services

Whether diluting harsh cleaning concentrates or collecting refuse with risk of unseen sharps, janitorial staff deserve hand coverage. Interlock gloves suit prolonged use across various maintenance tasks involving chemical and puncture exposure.

Some public use variants also include antimicrobial properties in the knit lining to protect against bacterial buildup and odors even with heavy community use.

Healthcare and Laboratory Work

Doctors, nurses, and laboratory technicians reach for interlock gloves to shield hands from bodily fluids or hazardous samples without losing tactile sensitivity. The latex-free construction also prevents skin irritation and allergic reactions sometimes sparked by rubber gloves.

In emergencies, first responders rely on flexible interlock protection when handling wounded people on stretchers or accident debris across hectic scenes. The knit material moves seamlessly with hands to aid life-saving tasks.

Conclusion

Interlock gloves represent a versatile hand protection option balancing durability, breathability, dexterity and ease of maintenance. Their innovative knit construction provides abrasion resistance and flexibility for detailed tasks across sectors like manufacturing, food service, transport, facilities and healthcare.

When selecting interlock gloves, first examine workplace hazard assessments and safety priorities for the intended activities. Also analyze environmental factors, duration of wear, product care options, and proper fit. Premium interlock gloves perfectly match key protective qualities with comfort and sensitivity to keep hands shielded from harm without limiting performance. We also provide the solution for driving gloves and all other types of gloves, even industry wise.

With the right knowledge of materials, protection grades and advanced features like touchscreen capability or liquid repellency, safety managers can make an informed decision on appropriate interlock glove choices for their personnel. This empowers a confident selection to match diverse working conditions and maximize value over thousands of hours of active use.